Soldering is an age-old craft that has evolved significantly throughout history. This article will explore the origins of soldering, major milestones in its development, and the modern applications of this timeless technique.

Soldering in Ancient Civilizations

Soldering was used as early as 4,000 BCE in Mesopotamia and Egypt for crafting intricate jewelry and decorative items. Ancient civilizations primarily used gold and silver alloys as solder, due to their low melting points and malleability.

Mesopotamia: Sumerians were among the first to use soldering techniques for creating beautiful gold and silver jewelry. They also applied soldering to create early forms of metal currency.

Egypt: The ancient Egyptians utilized soldering to join gold sheets in the construction of intricate jewelry, as well as for repairing broken items. Some of the most famous examples of soldering in ancient Egypt are found in the tomb of Tutankhamun.

Roman Empire: The Romans were known for their advanced metalworking skills, using soldering to create intricate metalwork for both practical and decorative purposes, including armor, tools, and jewelry.

An Egyptian Goldsmith Working at a Small Furnace (What some believe to be early forms of soldering)

Soldering Milestones

Introduction of lead-based solder: By the 15th century, lead-based solder became widespread, offering a lower melting point and increased strength. This development improved the overall efficiency and reliability of the soldering process.

Development of the soldering iron: The 19th century saw the invention of the soldering iron, providing better heat control and precision. Early soldering irons were heated on open flames, while later models used electrical heating elements.

Introduction of flux: In the early 20th century, flux was introduced to improve solder flow and prevent oxidation during the soldering process. Fluxes made from resin or organic acids significantly improved the quality and consistency of soldered joints.

Modern-Day Soldering Iron

Modern Soldering Applications

Electronics: Soldering plays a critical role in the assembly of electronic devices. It is used to create strong electrical connections between components and printed circuit boards, ensuring the proper functioning of devices such as smartphones, computers, and televisions.

Plumbing: Soldering is a common technique used to join copper pipes in plumbing systems. The process creates a watertight seal that prevents leaks and maintains the integrity of the plumbing system.

Automotive: Soldering is widely used in the automotive industry for assembling and repairing electronic components, such as control modules, sensors, and wiring harnesses.

Jewelry and metalworking: Soldering remains an essential skill in jewelry making and metalworking, as it allows artisans to create intricate designs and securely join metal pieces.

Advancements in Soldering Technology

Lead-free solder: With growing concerns about lead toxicity, lead-free solder options have become increasingly popular in recent years. These alternative materials, often based on tin and silver, provide similar performance while minimizing health risks.

Hot air soldering: Hot air soldering, also known as reflow soldering, allows for precise temperature control, resulting in cleaner and more efficient soldering. This technique is particularly well-suited for surface-mount components.

Surface-mount technology: This advancement has revolutionized the electronics industry, allowing for smaller, more compact devices. Surface-mount technology (SMT) relies on solder paste and reflow ovens, enabling automated assembly processes and improving manufacturing efficiency.

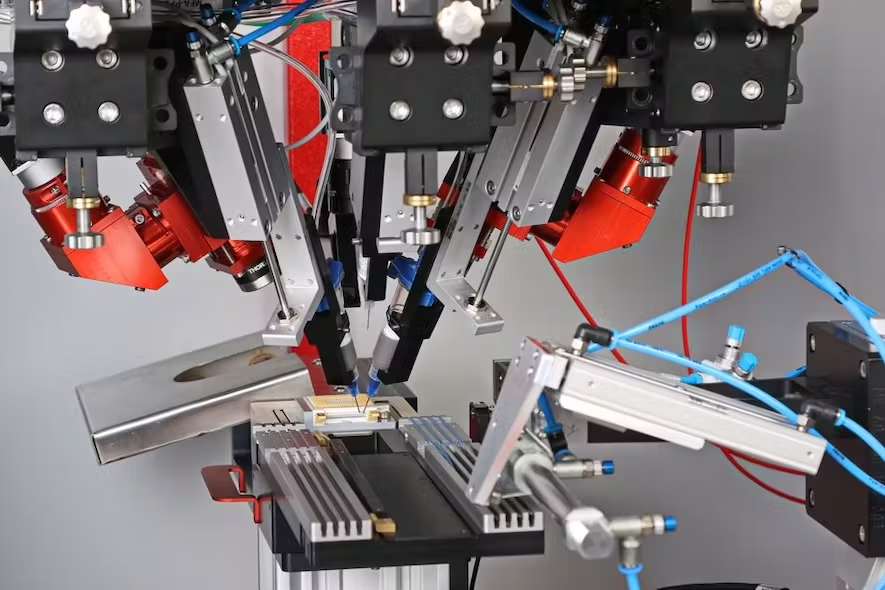

Soldering robots: In large-scale manufacturing settings, soldering robots have been developed to provide consistent, high-quality soldering. These machines can perform complex tasks with remarkable speed and precision, reducing human error and increasing productivity.

The Future of Soldering

Nanosoldering: As electronic devices continue to shrink in size, the need for more precise soldering techniques has arisen. Nanosoldering, which involves the manipulation of nanoparticles to create connections, offers a promising solution for working on microscopic scales.

Environmentally-friendly materials: As the world moves towards more sustainable practices, the development of environmentally-friendly soldering materials will likely become a priority. These materials will aim to minimize negative environmental impacts while maintaining performance standards.

Laser soldering: The use of lasers for soldering is an emerging technology that offers increased precision and control. This technique has the potential to improve soldering quality and reduce the risk of damaging sensitive components.

Pictured above is a selective laser soldering system from Nanosystec.

The evolution of soldering demonstrates the resilience and adaptability of this ancient craft. As technology continues to advance, soldering techniques and tools will undoubtedly evolve further, maintaining their relevance in an ever-changing world. From its humble beginnings in ancient civilizations to the cutting-edge advancements of today, soldering remains a vital technique across various industries, ensuring the secure joining of metal components and the successful function of countless devices.

Ethan